Phenol alkylation reaction with olefins and its applications. Characteristics of the feedstock and the resulting product. The device and principle of operation of the main apparatus. Technological calculation of the main apparatus and material balance of production.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Hosted at http://www.allbest.ru/

Ministry of Education and Science of the Russian Federation

Nizhnekamsk Petrochemical University

Specialty 240503 group 1711-z

FINAL QUALIFICATION WORK

Topic: Alkylation of phenol with propylene trimers(Pcapacity 125000 tons per year of alkyl phenol)

Fulfilled

checked

Introduction

1. Technological part

1.6.2 Specification of instrumentation and A

1.8 Industrial ecology of wastewater treatment in neonol production

2. Calculation part

2.2 Calculation of the main apparatus

Literature

Introduction

The relevance of the topic of this final qualification work "Phenol Alkylation with Propylene Trimers" is due to the fact that by now the foreign trade turnover of Russia is significantly ahead of the increase in industrial output in terms of growth rates. In general, this is a progressive trend, which is manifested in most developed countries of the world in the competitive struggle in the world market. In the course of this trade, an intensive exchange of scientific and technological achievements of individual countries is also carried out.

The state of the chemical, petrochemical industry largely depends on the all-Russian export. OAO NKNKH occupies a leading position among Russian manufacturers and exporters of petrochemical products. Practically all products manufactured by OAO NKNKH are in great demand on the foreign market, which is many times larger than the domestic market in terms of capacity.

Purpose of work: alkylation of phenol with propylene trimers.

Based on the goal, the following tasks of this work are distinguished:

1. Consider the theoretical foundations of the method for the production of phenol alkylation.

2. Make calculations in the production of phenol.

The structure of the work consists of an introduction, two chapters, a conclusion and a list of references.

1. Technological part

1.1 Theoretical foundations of the accepted method of production

Alkylation is the process of introducing alkyl groups into the molecules of organic substances.

The reaction of alkylation of phenol with olefins is the source of obtaining alkylphenol.

This method is high-temperature, it proceeds under the following conditions:

temperature? 85 - 125оС

pressure 0.4MPa

catalyst Levatit-SRC-108/4 BC.

Olefins are of paramount importance as alkylating agents. Alkylation with olefins proceeds according to the ionic mechanism through the formation of carbocations and is catalyzed by protic and aprotic acids. The reactivity of olefins is determined by their tendency to form carbocations:

RCH = CH2 + H+ - RC+H - CH3.

This means that the elongation and branching of the carbon atom chain in the olefin significantly increases its alkylation ability:

CH2=CH2< CH3 - CH = CH2 < CH3 - CH2 - CH = CH2 < (CH3)2C = CH2

Alkylation proceeds sequentially to form mono-, di-, and trialkylphenols, but simultaneously acid-catalyzed rearrangement occurs with the migration of ortho-alkyl groups to form para-isomers, which in this case are the most stable. Thus, the transformation scheme is as follows:

Phenol alkylation with olefins is accompanied by side reactions of olefin polymerization and destruction of alkyl groups. With the target direction of alkylation, these side processes are undesirable.

The alkylation reaction is carried out in an adiabatic reactor. The reaction products after alkylation are subjected to rectification. The degree of conversion of propylene trimers is 98.5%.

The ratio of phenol to propylene trimers is 4:1.

Carrying out the process of alkylation of phenol with propylene trimers is provided in a reactor with an axial input of raw materials.

The technological process of production is controlled by an automated control system using a computer and APACS+.

Heating of technological pipelines is provided by heating water with a temperature of 150°C. /2.245./

1.2 Characteristics of raw materials and finished product

Table 1. Characteristics of the feedstock and the resulting product

|

Name of raw materials, materials, reagents, catalysts, semi-finished products, manufactured products |

Number of state or industry standard, specifications, enterprise standard |

Quality indicators to be checked |

Norm according to GOST, OST or enterprise standard |

Purpose, scope |

|

|

Phenol brand "B" |

GOST23 51979 |

1. Appearance2. Crystallization temperature, °С not lower3. Mass fraction of non-volatile residue, % no more4. Optical density of an aqueous solution of phenol (0.8 g grade B in 100 cm3 (water) at 20 ° C, not more than5. Optical density of sulfonated phenol, no more6. Color of phenol melt according to platinum-cobalt scale, no more |

white liquid40,60,0080,03not standardized |

||

|

Propylene trimers |

TU2211031 |

1.Appearance |

transparent colorless liquid without mechanical impurities and insoluble moisture |

Used for the synthesis of alkylphenol |

|

2. Mass fraction of propylene trimers, % not less than3. Mass fraction of olefins C8 and below, % no more4. Mass fraction of olefins С10 and higher, % no more5. Mass fraction of moisture, % no more6. Bromine number, mg. bromine per 100 g of product, not less than7. Maleic numbermg. maleic anhydride per 1g. product, no more8. Mass fraction of paraffins,%, no more9. Mass fraction of peroxide compounds,%, no more10.Mass fractionionol, %. within |

95,02,03,00,021202,01,00,0005 |

||||

1. Appearance |

colorless transparentliquid |

||||

|

Technical caustic soda grade RR |

1. Appearance2. Mass fraction of sodium hydroxide, %, not less than3. Mass fraction of sodium carbonate,%, no more4. Mass fraction of sodium chloride,%, no more5. Mass fraction of iron in terms of Fe2O3,%, no more6. Sum of mass fractions of oxides of iron, aluminum, %, no moresodium sulfate, %, no more |

colorless transparentliquid42,00,50,050,00150,02 |

To neutralize the acidic environment of the alkylate |

||

|

Nitrogen gaseous and liquid high purity, 2nd grade |

1. Volume fraction of nitrogen, %, not less than2. Volume fraction of oxygen, %, no moreVolume fraction of water vapor in gaseous nitrogen, %, max |

99,950,05 |

It is used in the preparation of equipment for repair and for pressure testing of systems, for drying the spent catalyst |

||

|

Monoalkylphenols |

TU 38. 602 09 20 91 |

1.Appearance2. Color, units of the iodine scale, no more3. Mass fraction of monoalkylphenols, %, not less than4. Mass fraction of dialkylphenols, %, no more5. Mass fraction of phenol, %, no more6. Mass fraction of water, %, no more7. Flash point in an open crucible, °C, not lower |

Oily clear liquid1098,01,00,10,05 |

They are used in the production of ethoxylated monoalkylphenols (neonols), additives for lubricating oils, resins such as "Oktofor" |

Phenol (hydroxybenzene, carbolic acid) C6H5OH is a white crystalline substance with a specific "tar" smell, melting point 40.9 °C, boiling point 181.75 °C and density 1057.6 kg/m3. Soluble in water, forming with it an azeotropic mixture with a boiling point of 99.6 °C. Let's well dissolve in ethanol, diethyl ether, benzene, acetone, chloroform. It has slightly acidic properties and dissolves in aqueous solutions of alkalis with the formation of the corresponding phenolates. It is easily oxidized by air oxygen, forming oxidation products that turn it pink and then brown. In the form of vapours, dusts and solutions

toxic. In contact with the skin, phenol causes burns, in pairs it irritates the mucous membranes of the eyes and respiratory tract.

Phenol is one of the large-tonnage products of the main organic synthesis. Its world production is about 5 million tons. About half of the phenol produced is used in the production of phenol-formaldehyde polymers. Phenol is also consumed in the production of diphenylopropane, caprolactam, alkylphenols, adipic acid and various plasticizers.

C9H18 propylene trimers are a clear colorless liquid with a flash point of 21°C, a boiling point of 125°C and a density of 749 kg/m3. Sparingly soluble in water.

Monoalkylphenol is an oily transparent liquid with a boiling point of 250 ° C

Flash point 112оС and density 944 kg/m3. Does not dissolve in water. Monoalkylphenols with an alkyl group of 5-8 carbon atoms are strong bactericidal agents, and when extended to 8-12 carbon atoms, they turn out to be valuable intermediates for the synthesis of nonionic surfactants by their oxoethylation:

The most important field of application of alkylphenols and products of their further transformation is the production of stabilizers for polymers and oils against thermal-oxidative degradation that develops during the operation of these materials, especially at elevated temperatures. /3.750./

1.3 Description of the technological scheme

The process of alkylation of phenol with propylene trimers or olefins is carried out in the liquid phase in two reactors connected in series with the formation of a reactive cation. The catalyst generally attaches to the trimer or protonates it. The alkylating agent can also be a complex of a catalyst and a trimer.

The main reaction for the formation of monoalkylphenol (MAP) can be as follows: a fixed catalyst bed. The role of the alkylation catalyst is

С6Н6О + С9Н18 С15Н24О

Side reaction of the formation of dialkylphenol (DAF):

С15Н24О + С9Н18 С24Н42О

The alkylation reaction at an average temperature of 110°C proceeds with the release of heat 14.82 kcal/mol of propylene trimers.

Under the conditions adopted for the process, 0.083 mol of dialkylphenol is formed per 1 mol of monoalkylphenol.

The formation of by-product highly alkylated phenols depends on a number of factors, such as temperature, phenol to olefin ratio, residence time of the alkylate in the reaction zone, and the like.

The reaction mass (alkylate) after alkylation reactors on average contains:

- 0.60% wt. - trimers of propylene, paraffins;

- 32.65% wt. - phenol;

- 58.60% wt. - alkylphenols

- 7.65% wt. - dialkylphenols and others.

The phenol alkylation reaction with propylene trimers takes place in an adiabatic reactor at a pressure of 0.4 MPa (4 bar) and a temperature of 80°C to 125°C.

The temperature increase in the reactor occurs due to the release of heat during the exothermic reaction. The final temperature is determined by the performance of the catalyst, which loses its activity at 170°C. The speed of movement of the liquid relative to the free section of the reactor is 0.7 cm/sec, the residence time is 15 minutes. The activity of the catalyst decreases during operation and after 12-13 months of operation, the catalyst needs to be replaced. An increase in the temperature in the reactors has a significant effect on the performance of the catalyst; therefore, operation on a fresh catalyst requires a milder temperature regime for alkylation. The temperature of the bottom of the reactor is maintained at 70-800C.

At low loads, the reaction mixture is fed into the second reactor along the course with an initial temperature of 60-800C. The molar ratio of phenol: propylene trimers is kept at least 2:1. This is achieved by controlling the flow rate of the main streams - phenol and trimers of propylene or olefins - in the mixer pos. C-1.

Consumption of phenol in the mixer pos. C-1 is maintained by the flow regulator pos.6-6 installed on the supply line

phenol, and propylene trimers with a flow regulator pos.5-6. After mixing in the mixer pos. C-1 the reaction mixture enters the annular space of the refrigerator pos. T-1, where it is cooled by secondary cooling water to a temperature of 80°C. Return cooling water from the refrigerator pos. T-1 enters the shop return water collector.

From the refrigerator pos. T-1 the reaction mixture is fed to the alkylation in the first reactor pos. P-1a from the bottom along the process, the alkylate enters through the intermediate refrigerator pos. T-2, where it is cooled by secondary cooling water, to the lower part of the second reactor in the course of the process, pos. R-1b.

The temperature of the top of the first during the process of the reactor is maintained automatically by the temperature controller pos.11-7 by cooling the reaction mixture in the refrigerator pos. T-1 secondary cooling water, using the control valve pos. 11-12, which is installed on the secondary cooling water discharge line from the refrigerator pos. T-1.

The temperature of the top of the second reactor in the course of the process is maintained automatically by the temperature controller pos. 14-5 by cooling the alkylate in the refrigerator pos. T-2 secondary cooling water, the control valve of which pos. 14-11 is installed on the secondary cooling water discharge line from the cooler pos. T-2.

In order to avoid depressurization of the reactors in case of overpressure in them, coupled safety valves are installed.

Due to the fact that the alkylate has an acidic environment, to prevent corrosion of the workshop equipment, the alkylate from the second reactor in the process, pos. R-1b enters

mixer pos. C-2 for neutralization. The main neutralization of the alkylate is carried out with a 20 - 42% sodium hydroxide solution after the new reactor is put into operation with a fresh catalyst to pH = 6.5 - 7.0. Further maintenance of pH=6.5-7.0 is carried out by propylene trimers pH=7.0. The mixer is equipped with guide plates inside, due to which the flows are mixed.

From the container pos. E-2 into the mixer pos. C-2 alkali is supplied as needed by a plunger pump pos. H-2a, b. The dosage of alkali in the alkylate is made depending on the acidity of the alkylate.

From the mixer pos. C-2 neutralized alkylate enters the tank pos. E-3, while part of it is constantly diverted to the analyzer room for the chromatograph.

Alkylate in a container pos. E-3 is stored under a nitrogen “cushion” at a constant pressure, which is maintained automatically by the pressure regulator pos. 18-5.

1.4 Design and principle of operation of the main apparatus

alkylation phenol propylene

The main apparatus for carrying out the alkylation process is the reactor pos. R-1 a, b, intended for alkylation of phenol with propylene trimers.

The device is a vertical cylindrical vessel pos. 1 from the top pos. 3 and lower pos. 2 lids made of stainless steel. The cylindrical part is connected to the lid and the bottom with studs. Flange connections are made according to the "thorn - groove" type. Between the cylindrical part and the bottom there is a lattice pos. 4 for holding the catalyst bed. The grid is a longitudinal and transverse metal plate, covered with a mesh with a fine mesh in the light of 0.25x0.25mm, which eliminates the failure of the catalyst. The catalyst inside the apparatus is located according to the bulk method. The reaction mixture passes through the catalyst bed, where the alkylation reaction takes place on the active sites of the catalyst. Alkylate leaves the reactor through the filter pos. 5, built into the center of the fitting pos. 3. The filter is a cylinder with many holes, covered with a metal mesh with a fine mesh in the light of 0.25x0.25mm.

A fitting pos. And to enter the reaction mixture, the exit of the reacted mixture is carried out through the fitting pos. B, embedded in the top cover. The catalyst is loaded through the fitting pos. B, installed in the reactor lid at an angle to the main axis of the apparatus, unloading occurs fitting pos. Zh, located at the bottom of the cylindrical part of the apparatus, which can also be used as a hatch for mounting and inspecting internal devices. At the lower point of the apparatus, a fitting pos. D, designed to empty the reactor from the product before unloading the catalyst and repairing the apparatus.

Outside, a support consisting of a skirt and ten paws is welded to the cylindrical part. Specifications:

1. Capacity 10.3 m3

2. The environment in the device is toxic, explosive

3. Working pressure 0.4Mpa

4. Working temperature 95 0C

5. Main material Steel Х18Н10Т

6. Machine weight 5030 kg

7. Dimensions:

a) height 9550 mm

b) diameter 1200 mm

/4.86/

1.5 Analytical production control

GOST 14870-77 Measurement of moisture concentration by the Fisher method

The method consists in dissolving or dispersing the sample in an appropriate solvent and titrating with the Karl Fischer reagent, which is a mixture of iodine, sulfur dioxide, pyridine and methanol. In the presence of water, iodine reacts with sulfurous anhydride to form colorless hydroiodic acid and sulfuric anhydride according to the following reaction equation:

С5Н5 I2 + С5Н5N SO2 + С5Н5N + H2O + CH3OH

2С5Н5N HI + С5Н5N HSO4 CH3

The end point of the titration is taken as the moment of appearance of free iodine, determined electrometrically or visually.

This method determines hydroscopic, crystallization, sorbed water.

Chromatographic Method No. 307-007-92

The method is based on the chromatographic separation of the mixture components with their subsequent registration at the outlet of the chromatographic column by a thermal conductivity detector.

Chromatographic method TU 2211-031 05766801

The method is based on the separation of the components of the analyzed sample on a chromatographic column with their subsequent registration by a system connected to a flame ionization detector.

Potentiometric Method #8 pH Measurement

The technique is designed to measure the pH of water condensate, waste and industrial water. Measurement method The pH value corresponds to the negative decimal logarithm of the activity of hydrogen ions in a solution of pH=-lg an. The pH is a measure of the acidity or alkalinity of a solution.

Table 2.18 Determination of the environment of aqueous solutions

GOST 4333 - 87

The essence of the method is to heat a sample of an oil product in an open crucible at a set speed until a flash of vapor (flash point) of the oil product above its surface from an incendiary device occurs and until the product ignites (ignition temperature) with a burning duration of at least 5 second.

GOST 14871 - 76

Color is a conditionally accepted quantitative characteristic for liquid chemical reagents and their solutions, which have a slight color.

The method is based on the determination of color by visual comparison with the color scale.

1.6 Automation of production

1.6.1 Description of the raw material flow control circuit

803-1 - diaphragm DK 25-100

803-2 - overpressure sensor Metran-100 DD-2430

803-3 - HID 2029 IS Barrier

803-4 - HID 2037 IS Barrier

803-5 - EPP-Ex electropneumatic positioner

803-6 - single-seated control valve - type NZ RK201nzh

Description of the reflux flow control circuit in Kt-2

The differential pressure from the diaphragm (pos. 803-1) is fed to the overpressure sensor with a built-in microprocessor Metran-100 DD-2430 (pos. 803-2). The normalized electrical signal of 4 - 20 mA from the sensor through the HID 2029 intrinsic safety barrier (pos. 803-3) is fed to the controller, where it is recorded and compared with the previously set value. If there are deviations of the measured parameter from the set value, the APACS system generates a control action on

single-seat control valve - type NZ RK201nzh (pos. 803-6) through the HID 2037 intrinsic safety barrier (pos. 803-4) and through the electro-pneumatic positioner EPP-Ex (pos. 803-5) until the mismatch becomes zero .

Figure 1. Flow contour of propylene trimers to C-3 mixer

1.6.2 Specification of instrumentation and control equipment

Table - Specification of instrumentation and control equipment

|

Position number |

Name parameter |

instrument settings |

Controlled environment |

Name and characteristics of the device |

Instrument model |

Quantity (pcs) |

|

|

Pressure control in the pipeline of propylene trimers |

On the pipeline |

propylene trimers |

Metran - 100-Ex-DI-3141-MP |

||||

|

Flow control of propylene trimersB E-1 |

In the pipeline |

propylene trimers |

Type DK 25200 GOST 8.563.1 |

||||

|

On the pipeline |

Metran-100-Ex-DD-2430-MP |

||||||

|

IS Barrier Cabinet |

4-20 mA, output from 4-20 mA |

||||||

|

IS Barrier Cabinet |

4-20 mA, output from 4-20 mA |

||||||

|

On the valve |

|||||||

|

On the pipeline |

|||||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Temperature in E-1 |

On the pipeline |

propylene trimers |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Pressure regulation in E-1 |

On the pipeline |

Metran - 100-Ex-DI-3141-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. 4-20mA input, 4-20mA output |

||||||

|

On the valve |

Designed for the move |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

||||||

|

Flow control of propylene trimers in C-1 |

In the pipeline |

propylene trimers |

The diaphragm is chamber, installed in the flanges of the DSK pipeline in accordance with GOST 8.563.1, 8.563.2, 8.563.3. |

Type DK 25200 GOST 8.563.1 |

|||

|

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal in HART protocol or digital signal based on RS485 interface for differential pressure input. |

Metran-100-Ex-DD-2430-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

On the valve |

10…100 mm. Explosion protection: ExdsllB+H2T6 |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

||||||

|

Regulation of the consumption of phenol C-1 |

In the pipeline |

The diaphragm is chamber, installed in the flanges of the DSK pipeline in accordance with GOST 8.563.1, 8.563.2, 8.563.3. |

Type DK 25200 GOST 8.563.1 |

||||

|

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal in HART protocol or digital signal based on RS485 interface for differential pressure input. |

Metran-100-Ex-DD-2430-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

On the valve |

Electropneumatic positioner. Supply air pressure 0.14 MPa. Input signal 0.02-0.1 MPa. Designed for a stroke of 10 ... 100 mm. Explosion protection: ExdsllB+H2T6 |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

||||||

|

Temperature of alkylate up to T-4 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Temperature of alkylate after T-4 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Pressure control of alkylate at the inlet to R-5 |

On the pipeline |

The Metran-100-Di-Ex intelligent pressure sensor is designed to measure and continuously convert to a unified analog current signal of 4-20 mA and / or a digital signal based on the RS485 interface, the output signal of overpressure |

Metran - 100-Ex-DI-3141-MP |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

Regulation of the flow of industrial water at the outlet of T-4 |

In the pipeline |

industrial water |

The diaphragm is chamber, installed in the flanges of the DSK pipeline in accordance with GOST 8.563.1, 8.563.2, 8.563.3. |

Type DK 25200 GOST 8.563.1 |

|||

|

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal in HART protocol or digital signal based on RS485 interface for differential pressure input. |

Metran-100-Ex-DD-2430-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

On the valve |

Electropneumatic positioner. Supply air pressure 0.14 MPa. Input signal 0.02-0.1 MPa. Designed for the move 10…100 mm. Explosion protection: ExdsllB+H2T6 |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

||||||

|

Top temperature R-5 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

IS Barrier Cabinet |

IS barrier with galvanic isolation, output. Hazardous zone signal (input) - 4-20 mA. Safe area signal (output) - 4-20 mA. Power supply 24 V DC. Single channel. |

||||||

|

Shut-off valve, 0% closed, 100% open |

|||||||

|

Middle temperature R-5 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Bottom temperature R-5 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

P-5 pressure control |

On the pipeline |

The Metran-100-Di-Ex intelligent pressure sensor is designed to measure and continuously convert to a unified analog current signal of 4-20 mA and / or a digital signal based on the RS485 interface, the output signal of overpressure |

Metran - 100-Ex-DI-3141-MP |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

Regulation of the flow of industrial water at the outlet of T-6 |

In the pipeline |

industrial water |

The diaphragm is chamber, installed in the flanges of the DSK pipeline in accordance with GOST 8.563.1, 8.563.2, 8.563.3. |

Type DK 25200 GOST 8.563.1 |

|||

|

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal in HART protocol or digital signal based on RS485 interface for differential pressure input. |

Metran-100-Ex-DD-2430-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

On the valve |

Electropneumatic positioner. Supply air pressure 0.14 MPa. Input signal 0.02-0.1 MPa. Designed for the move 10…100 mm. Explosion protection: ExdsllB+H2T6 |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

||||||

|

Top temperature R-7 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Middle temperature R-7 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Bottom temperature R-7 |

On the pipeline |

A thermal converter with a unified signal is designed to measure the temperature of neutral and aggressive media, used in explosive areas. 4-20mA DC Unified Output Range |

TSP Metran-256 |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Pressure control R-7 |

On the pipeline |

The Metran-100-Di-Ex intelligent pressure sensor is designed to measure and continuously convert to a unified analog current signal of 4-20 mA and / or a digital signal based on the RS485 interface, the output signal of overpressure |

Metran - 100-Ex-DI-3141-MP |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

Level control in E-8 |

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and / or a digital signal in the HART protocol standard, or a digital signal based on the RS485 interface of hydrostatic pressure |

Metran-100-DG-Ex |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

alkylate pH after alkylation reactors |

in the pipeline |

Electrode with built-in temperature sensor Pt -100, length 120mm, diameter 12mm. The temperature of the measured medium is 0-120оС. The range of the measured medium is 0-14. |

|||||

|

On the pipeline |

Measuring pH meter transducer with crystal display. Output signal 4h20 mA, measurement error 0.1%. Ambient temperature -20 h +55 °С |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from 4-20 mA |

||||||

|

Controlling the consumption of alkylate at the outlet of the reactors |

In the pipeline |

The diaphragm is chamber, installed in the flanges of the DSK pipeline in accordance with GOST 8.563.1, 8.563.2, 8.563.3. |

Type DK 25200 GOST 8.563.1 |

||||

|

On the pipeline |

Metran-100 series intelligent pressure sensor is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal in HART protocol or digital signal based on RS485 interface for differential pressure input. |

Metran-100-Ex-DD-2430-MP |

|||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

Pressure regulation in E-11 |

On the pipeline |

Intelligent pressure sensor series Metran-100-Di-Ex is designed to measure and continuously convert into a unified analog current signal 4-20 mA and/or digital signal based on RS485 interface overpressure output |

Metran - 100-Ex-DI-3141-MP |

||||

|

IS Barrier Cabinet |

Intrinsic safety barrier of the HID series input, two-channel. 4-20mA input, 4-20mA output |

||||||

|

IS Barrier Cabinet |

HID series intrinsic safety barrier output, two-channel. Input signal from 4-20 mA, output from |

||||||

|

On the valve |

Electropneumatic positioner. Supply air pressure 0.14 MPa. Input signal 0.02-0.1 MPa. Designed for a stroke of 10 ... 100 mm. Explosion protection: ExdsllB+H2T6 |

||||||

|

On the pipeline |

Pneumatic control valve actuator |

1.7 Occupational health and safety

Requirements for ensuring the explosion hazard of the phenol alkylation process.

The projected plant for the production of alkylphenols is located in close proximity to large enterprises: NShZ, the Elastic plant, CHPP-1, OAO NKNKh near the city of Nizhnekamsk, taking into account the “wind rose”. The winds prevailing here carry a significant part of harmful emissions in the opposite direction from residential areas. Technological equipment is located on an outdoor unit measuring 24 by 24 meters and 17 meters high. The process control is automated and carried out remotely using the APACS system from the control room building. The dimensions of the control room are 15 by 20 meters and the height is 4 meters.

Based on the properties of substances according to fire safety standards NPB 105-03, we establish the category and class of the explosive zone: for the operator category “D”, and for production category “An”. According to PB 09.107-03, in terms of the energy potential of the explosion and the amount of explosive substances, the process belongs to category I, since Q > 54 and m > 9600 kg.

According to the PUE, the outdoor installation belongs to the class of the explosive zone - V-1g.

According to GOST 12.2.007.0-75 for electrical products at outdoor installations and in the control room, a three-phase four-wire dead-earthed electrical network U = 380/220V is used. In accordance with the PUE, in terms of the degree of danger of electric shock, an outdoor installation is equated to especially dangerous premises, the control room belongs to premises without increased danger.

According to the degree of danger of electric shock to people, the control room belongs to the class of increased danger. For the control room, according to the PUE, the minimum permissible degree of protection of electrical equipment corresponds to IP44 (against the ingress of solid substances with a diameter of more than 1 mm and splashing water in any direction).

In accordance with GOST 12.1.019-79 and GOST 12.1.009-76, the electrical safety of personnel is ensured by the design solutions of electrical installations; use of protective grounding of all equipment, placement of DCS electrical equipment in closed cabinets.

All designs of electrical equipment comply with operating conditions and provide protection for personnel from contact with live parts.

To prevent damage to the insulation from the action of moisture, the entire cable industry is sealed in piping.

Sources of ignition are: hot or heated walls of equipment, sparks from electrical equipment, static electricity, impact and friction sparks.

Buildings and structures of the projected production are made of reinforced concrete and belong to the II degree of fire resistance.

In preparation for repair, the apparatus is purged with nitrogen. All equipment and connections are sealed. Repair work is carried out only with a spark-proof tool. For the purpose of timely detection of a fire, an automatically operating alarm system is provided. The premises are provided with an electric fire alarm system to detect the initial stage of a fire with manual and automatic activation. For manual activation, push-button detectors of the PKIL-9 type are used. For automatic activation, smoke detectors of the DI-1 type are used. In an explosive environment, explosion-proof detectors DSP-1AG (differential) are used.

To extinguish a fire in the workshop, the following primary fire extinguishing agents are provided: fire water supply, fire extinguishers, asbestos blankets, sand, nitrogen,

water vapor. Fire monitors and fire hydrants are located along the perimeter of the workshop.

Carbon dioxide and powder fire extinguishers OU-8, OU-25, OP-100 are used to extinguish electrical equipment.

A fire communication system is in place for the purpose of timely notification of a fire, as well as calling fire brigades.

According to the fire-technical classification, the buildings meet the necessary requirements for the safe evacuation of people through emergency exits. The number of emergency exits is two.

To avoid thermal burns, equipment and pipelines with high wall temperature are insulated with mineral wool and galvanized metal sheets.

To protect the devices from excess pressure in excess of the allowable, safety valves of the brand PPK4-150-40, PPK4-125-40 are used.

During the extraction process, it is necessary to measure the temperature, pressure and level in the apparatus, as well as the flow rate of incoming products.

To measure the pressure, an intelligent overpressure sensor from the Metran company in an explosion-proof design is used. The level is measured with a digital buoy level sensor from Masoneilan

in explosion-proof execution. To measure the temperature, we use a platinum resistance thermocouple. The flow rate is measured with a chamber diaphragm for pipelines manufactured by Metran. The process is controlled remotely from the operating room.

The controller ensures the maintenance of the specified process parameters and the speed of regulation, provides signaling and blocking when the parameters deviate from the permissible values according to the specified program.

1.8 Industrial ecology

Protection of the water basin from industrial effluents.

The phenol alkylation unit with propylene trimers has the following emissions into wastewater of OAO NKNKh in Table 4.

Waste water is generated: during the preparation of capacitive and heat exchange equipment for repair (1 time per year). They are dumped into the HZK through wells. MPC for reservoirs of sanitary and household water use is set for phenol 0.1 mg/l. MPC for fish - economic waters for phenol 0.025 mg / l.

Table 4. Wastewater

Effluent from the CPC enters the BOS. The norms for draining water CZK, COD are not higher than 500 mg / l, pH - 6.5 h 12.5, in case of discrepancy, effluents are squeezed out for organic stripping. The state of the water is analyzed for COD by the bichromate method No. 25.

To protect reservoirs from harmful emissions and prevent soil pollution, the workshop is equipped with trays and underground tanks for collecting atmospheric precipitation, from which, as it accumulates, effluents are pumped into a chemically contaminated sewer.

Methods for the treatment of industrial wastewater are usually divided into mechanical, chemical, biological and physico-chemical. By these methods, waste water is conditioned for subsequent treatment, or completely purified from impurities.

In this case, purification can be carried out both with the release of impurities into the gaseous, solid or liquid phase, and with their destruction.

2. Calculation part

2.1 Material balance of production

Initial data:

(94) (126) (220)

С6Н6О + 2 С9Н18 = С24Н42О - side reaction of formation

(94) (126) (346)

dialkylphenol. (2)

Plant capacity for alkylphenol is 125000

tons per year.

The calendar fund of time is 365 days.

Time spent on overhaul - 10 days.

The conversion for propylene trimers is 98.5%.

The composition of the reaction mixture (% mass)

Propylene trimers - 40

Alkylate Composition (% wt)

Alkylphenol - 58.60

Including:

Phenol - 32.65

Propylene trimers - 0.60

Dialkylphenol -7.65

The process is considered continuous.

We draw up a diagram of material flows

Figure 2.1 Material flow diagram for alkylphenol production

R - phenol alkylation reactor with propylene trimers; G1 - material flow of phenol and propylene trimers, respectively; G2 - feed column Kt-1, alkylate

Effective equipment operation fund (hour)

Tef \u003d Tk -? Tr

Tef \u003d 365 24 - 10 24 \u003d 8520 hours

Productivity on alkylphenol (kg/h)

Alkylphenol

X=8597.42 kg/h

X=4790.20kg/h

Propylene trimers

heavy residue

Dialkylphenol

X=1122.36kg/h

Feed column Kt-1 - alkylate reactor R-1 (stream G2). Based on the conversion by propylene trimers, we determine the amount of raw material fed. We calculate the number of participants in the reaction (1) (kg / h)

Propylene trimers

We calculate the number of participants in the reaction (2) (kg / h)

Propylene trimers

We determine the total number of substances that took part in reactions (1) and (2)

Propylene trimers

We calculate the amount of raw materials supplied (kg / hour)

Propylene trimers

Compiling a material balance table

Table 5. Summary table of material balance

2.2 Calculation of the main apparatus

2.2.1 Technological calculation of the main apparatus

Purpose: Alkylation of phenol with propylene trimers is carried out in the liquid phase in the presence of a catalyst.

The amount of raw material entering the reactor

Gр=26784.11 kmol (see material balance)

Working mode:

P = 0.4 MPa (4 kmol/cm2)

Volumetric feed rate of the reaction mixture 7.2 h-1

Catalyst

Service life of the catalyst - 12-13 months

Cross-sectional area of the device:

where: Vf? volumetric flow rate of the reaction mixture, m3/s;

W - linear flow velocity in the apparatus, m/s.

Machine diameter:

D = 1.13 v1 = 1.13 m

We accept a reactor with a diameter of 1200 mm.

Required amount of catalyst:

Vob - volumetric feed rate of raw materials, hour-1;

Vob = 7.2 h-1 = 0.002 s-1

The volume of catalyst required for the process is 5 m3, therefore, the height of the catalyst layer corresponding to this volume is determined by the formula:

Reactor height calculation. The height of the reactor is determined by the following characteristics:

Hreak.zone = 7 m - the height of the reaction zone;

Nkat. dec. = 0.035 m - the height of the catalyst lattice;

Nshtuts. = 0.55 m - the height of the fittings to be installed;

Ndn. = 1 m - bottom height;

Hkr = 1 m - cover height.

Hreact \u003d 7 + 0.035 + 0.55 + 1 + 1 \u003d 9.5 m.

We accept a reactor with a height of 9550 mm.

Therefore, two reactors are accepted for the installation to ensure maximum conversion with the following main characteristics:

diameter - 1200 mm;

height - 9550 mm;

catalyst bed height - 5.35 m;

catalyst volume 5 m3.

The calculation of the R-1v reactor is carried out in a similar way, the calculation data are summarized

to table 6

Table 6. Characteristics of the reactor equipment

2.2.2 Thermal calculation of the apparatus

Initial data:

The reaction mixture enters the reactor at a temperature of 70 0C.

Heat loss to the environment is 1.1% of heat gain.

Other data from the material balance.

Based on the scheme of heat flows, we make up the heat balance equation.

Q1 + Q2 = Q3 + Q4 - equation for the first reactor,

Q5 + Q6 = Q7 + Q8 - equation for the second reactor.

Determine the amount of heat supplied with the reaction mixture

Q1 = G1 Ср1 t1

G1 - the amount of incoming raw materials, kmol;

Ср1 - specific heat of the reaction mixture, kJ/kg·K;

t is the temperature of the reaction mixture, 0С.

G1 \u003d 26784.11 kg / h \u003d 7.44 kmol

Let us determine the specific heat of the reaction mixture

Cp (phenol) = 2344.98

The composition of the reaction mixture:

Phenol - 60%,

Propylene trimers - 40%.

Ср = У сpi wi

Cр = 2344.98 0.60 + 2027.3 0.40 = 2217.90

Cp = 2217.9 = 2.218

The amount of heat supplied with the reaction mixture

Q1 = 7.44 2.218 70 = 1155.13 kW

Let us determine the amount of heat released as a result of exothermic reactions

C6H6O + C9H18 \u003d C15H24O - the target reaction for the formation of alkylphenol; (1)

C6H6O + 2 C9H18 \u003d C24H42O - a side reaction of the formation of dialkylphenol. (2)

Q2 = Q1int + Q2sp,

Q1tsel - the amount of heat released as a result of the exothermic reaction (1),

Q2b - the amount of heat released as a result of the exothermic reaction (2).

Q1tsal \u003d G1? Нр

Q2pob \u003d G2? Нр,

Нр1, ?Нр2 - enthalpy changes as a result of reactions (1) and (2), kJ/kg;

G1, G2 - the amount of alkylphenol and dialkylphenol formed after the first reactor (30% alkylphenol and 1% dialkylphenol from the formed alkylate 26784.11 kg/h), kmol.

Нр1 = 281.56 kJ/kg

Нр2 = 106.52 kJ/kg

G1 \u003d 8035.23 kg / h \u003d 2.23 kmol

G2 = 267.84 kg/h = 0.07 kmol

Q1int \u003d 2.23 281.56 \u003d 627.87 kW

Q2sp = 0.07 106.52 = 7.46 kW

Q2 = 627.87 + 19.70 = 635.33 kW

We determine the amount of heat leaving with alkylate from the heat balance equation for the first reactor

Q1 + Q2 = Q3 + Q4

Q3 = Q1 + Q2 - Q4,

but for this it is necessary to find Q4 - losses to the environment.

Q4 = (Q1 + Q2) 1.1%

Q4 = (1155.13 + 635.33) 0.011 = 19.70 kW

From here we find Q3

Q3 = 1155.13 + 635.33 - 19.70 = 1770.76 kW

Determine the temperature of the reaction mixture at the outlet of the first reactor

G3 - amount of formed alkylate, kmol

Ср3 - specific heat capacity of alkylate, kJ/kg K.

G3 \u003d 26784.11 kg / h \u003d 7.44 kmol

Determine the specific heat capacity of the alkylate

Cp (phenol) = 2344.98

Cp (propylene trimer) = 2027.3

Cp (alkylphenol) = 2450.63

Cp (dialkylphenol) = 2373.48

The composition of the alkylate:

phenol - 49%,

propylene trimers - 20%,

alkylphenol - 30%,

dialkylphenol - 1%.

Ср = У сpi wi

Av = 2344.98 0.49 + 2027.3 0.20 + 2450.63 0.30 + 2373.48 0.01 =

2313,42 = 2,313

Compiling a heat balance table for the first reactor

Table 7. Heat balance for the first reactor

Determine the amount of heat leaving with the refrigerant from the heat exchanger

Qwater \u003d Gwater Srwater (t2k - t2n)

Gwater - cooling water consumption, kmol;

Srvody - specific heat capacity of water, ;

t2k, t2n - final and initial water temperature, 0C.

Similar Documents

The process of alkylation of phenol with olefins. Thermodynamic analysis. Dependence of the mole fraction of components on temperature. Adiabatic temperature difference in the reactor. Protonation of an olefin to form a carbocation. Oxidative ammonolysis of propylene.

term paper, added 01/04/2009

Phenol as a chemical substance, its uses and significance. Features of the stages of obtaining phenol. Brief description of the process of its production through benzenesulfonic acid, chlorobenzene, isopropylbenzene, oxidative chlorination of benzene. Types of raw materials.

abstract, added 02/18/2011

Methods for obtaining phenol. Discovery of zeolite catalysts for the oxidation of benzene with nitrous oxide. The nature of the catalytic activity of zeolites. New ways of synthesis of phenol. The active state of iron in the zeolite matrix. Biomimetic properties of oxygen.

abstract, added 04/24/2010

The concept and nomenclature of phenols, their basic physical and chemical properties, characteristic reactions. Methods for obtaining phenols and the scope of their practical application. The toxic properties of phenol and the nature of its negative impact on the human body.

term paper, added 03/16/2011

Classification, physical and chemical properties of phenols. The study of the structure of the molecule. Effect of the benzene ring on the hydroxyl group. Dissociation and nitration of phenol. Its interaction with sodium, alkalis. Reactions of oxidation, substitution and hydrogenation.

presentation, added 02/17/2016

The ratio of benzene to KMnO4 solution and bromine water, benzene nitration. Oxidation of toluene, safety precautions, operations with toluene. Interaction of molten phenol with sodium, alkali solution, displacement of phenol from sodium phenolate by carbonic acid.

laboratory work, added 02.11.2009

The toxic effect of phenol and formaldehyde on living organisms, methods for their qualitative determination. Quantitative determination of phenol in samples of natural waters. Method for determining the minimum detection concentrations of organic toxicants in water.

term paper, added 05/20/2013

Characterization of industrial methods for the alkylation of benzene with propylene. Principles of alkylation of benzene with olefins in chemical technology. Problems of designing technological installations for benzene alkylation. Description of the technology of the production process.

thesis, added 11/15/2010

Titrimetric method of analysis. Theory of the bromatometric method of analysis. Titration technique. Advantages and disadvantages of the bromatometric method. Phenols. Determination of phenol. Chemical reactions used in titrimetry methods.

term paper, added 03/26/2007

Description of the technological scheme of the process and auxiliary materials. Material balance in the processing of saturated gases. Calculation of the main apparatus - stabilization column. Calculation of raw material input temperature. Definition of internal material flows.

Since phenols interact with aluminum halides and other Lewis acids to form salts of the ArOAlCl 2 type, their direct alkylation under the conditions of the Friedel-Crafts reaction cannot be carried out. Phenols are alkylated with alkenes and alcohols under acid catalysis. Sulfuric, hydrofluoric, phosphoric acids or KU-2 cation exchangers, doux and other cation exchange resins are preferred as catalysts. Thus, sterically hindered phenol, 2,6-di-tert-butyl-4-methylphenol (ionol), is obtained industrially from cresol and isobutylene, which is widely used to stabilize polymers.

Similarly, 2,4,6-triisopropylphenol is obtained from phenol and isopropyl alcohol.

Acylation of phenols under the classical conditions of the Friedel-Crafts reaction with a complex of acyl halide and aluminum chloride also leads to unsatisfactory results, since the phenol hydroxyl group undergoes acylation. This modification of this method is more effective when a complex of carboxylic acid and boron trifluoride is used as an acylating agent. In this case, the acyl group is introduced almost exclusively in the para-position of the benzene ring. So, for example, phenol, when interacting with a complex of acetic acid and BF 3, gives para-hydroxyacetophenone in 95% yield.

The most common method for the preparation of aromatic hydroxyketones is based on the Fries rearrangement. K. Fries in 1908 found that aryl esters of carboxylic acids, when heated with AlCl 3 or AlBr 3, rearrange into isomeric ortho- or para-hydroxyketones. As a rule, as a result of the rearrangement, a mixture of ortho- and para-isomers is formed without an admixture of the meta-isomer.

The ratio of ortho- and para-isomers depends mainly on temperature and solvent. Under more stringent conditions, ortho-hydroxy ketone predominates, and at 20-25 about C - para-hydroxy ketone.

The mechanism of the Fries rearrangement seems to be intermolecular acylation of the ortho- or para-position of the benzene ring of the aryl ester by the complex of the second molecule of the ester and AlCl 3 to form the acyl derivative of hydroxyketone and phenol.

The rearrangement ends with the intermolecular transfer of the acyl group to the phenol.

Unlike the phenols themselves, their ethers very readily undergo regioselective Friedel-Crafts acylation under mild conditions to form para-alkoxyaryl ketones. The best results are achieved by acylation of phenol ethers with acyl halides in methylene chloride at 0°C in the presence of two moles of AlCl 3 or AlBr 3 .

The condensation of phenols with phthalic anhydride in the presence of sulfuric acid or zinc chloride (A. Bayer, 1874) should be considered as one of the varieties of the Friedel-Crafts acylation reaction. In this case, two phenol molecules condense with one phthalic anhydride molecule to form triphenylmethane derivatives called phthaleins.

Phenols form inactive ArOAlCl2 salts with AlCl3; therefore, for the alkylation of phenols, protic acids or acid-type metal oxide catalysts are used as catalysts. This allows only alcohols and olefins to be used as alkylating agents. Along with the substitution products in the core, some phenol ethers are obtained, which are easily rearranged into alkylphenols:

It has been found, however, that alkylphenols are predominantly formed by direct alkylation to the core. The mechanism of this reaction is similar to that considered earlier for aromatic hydrocarbons, and the OH group of phenols strongly activates especially the 4- and 2-positions with almost complete absence of meta-isomers in the products.

Alkylation proceeds sequentially with the formation of mono-, di- and trialkylphenols, but simultaneously acid-catalyzed rearrangement occurs with the migration of ortho-alkyl groups to form para-isomers, which in this case are the most thermodynamically stable.

Of the monoalkylphenols catalyzed by protic acids, the para isomer always predominates; with an increase in the activity of the catalyst, the temperature and duration of the reaction, the proportion of this isomer among the monosubstituted ones can increase from 60–80 to 95% or more due to the isomerization of the ortho-isomer.

Of the disubstituted, 2,4-dialkylphenol always predominates significantly, the proportion of which increases even more under the conditions indicated above.

With the sequential introduction of alkyl groups, in contrast to the alkylation of aromatic hydrocarbons, the first stage proceeds faster than the second, and the second, in turn, faster than the third. The composition of the products of sequential substitution is also affected by the reversible transalkylation reaction

R2C6H3OH + C6H5OH? 2RC6H4OH

whose equilibrium is shifted to the right. Therefore, with an increase in the activity of the catalyst, the temperature and duration of the reaction, the content of monoalkylphenol in the resulting mixture can significantly increase.

In addition to phenol ethers and polyalkyl-substituted phenols, alkylation by-products are polyolefins and the resulting longer-chain alkylphenols. On the contrary, when reacting with higher, especially with branched olefins, their depolymerization is observed to obtain alkylphenols having a shorter alkyl group. A common method for suppressing these side reactions is to lower the temperature, since alkylation has the lowest activation energy (? 20 kJ/mol). In order to avoid polymerization of the olefin, it is also necessary to reduce its concentration in the liquid, which is achieved by the gradual introduction of the olefin into the reaction mass.

The reactions of phenols with isoolefins are largely reversible, and heating the corresponding alkylphenols with an acid catalyst leads to the release of the olefin:

Isomerization and transalkylation proceed in part by this reaction.

Sulfuric acid is most often used as catalysts - protic acids - in industry. It is the most active among other available and cheap acids, but at the same time, it also catalyzes side reactions more strongly, leading additionally to phenol sulfonation and olefin sulphation and forming phenol sulfonic acids HOC6H4SO2OH and ROSO2OH monoalkysulfates, which also participate in the catalysis of the process. With sulfuric acid, alkylation with n-olefins (except for ethylene) occurs at 100–120 °C, and with more reactive isoolefins and styrene, already at 50 °C; however, to speed up the process, in the latter case, alkylation is carried out at ? 100 °С, using H2SO4 in the amount of 3…10%.

Another catalyst that does not cause side reactions of sulfonation and is milder in its action is p-toluenesulfonic acid. However, it is less active and more expensive than sulfuric acid. With these catalysts, phenol alkylation proceeds as a homogeneous reaction.

Their common disadvantage is the need to wash off the acid catalyst, resulting in the formation of a significant amount of toxic wastewater. Therefore, heterogeneous catalysts are widely used, especially cation exchange resins, which are separated from the reaction mass by simple filtration.

The ortho-alkylation of phenols is carried out by catalysis with aluminum phenolates (ArO)3A1. In this case, even when the para-position is not occupied, the alkyl group is predominantly directed to the ortho-position with the successive formation of mono- and dialkylphenols.

The gas-phase alkylation process is only applicable to the methylation of phenol with methanol. It is carried out with a heterogeneous acid-type catalyst (aluminum oxide, aluminosilicates, etc.).

Process technology

A batch process is often used for the alkylation of phenols. In the alkylation with high-boiling liquid olefins, the reaction is carried out in an apparatus with a stirrer and a jacket for heating with steam or cooling with water. Phenol and a catalyst are loaded into it, heated to 90 °C, after which liquid olefin (diisobutene, propylene trimer or tetramer, styrene) is fed with stirring and cooling. In the second half of the reaction, on the contrary, it is necessary to heat the reaction mass. The total duration of the operation is 2–4 hours. After that, the reaction mass is neutralized in a mixer (5% alkali, taken in an equivalent amount to the acid-catalyst), heating the mixture with live steam. This distills off the unreacted olefin, which, after vapor condensation, is separated in the separator outlets and can be reused for alkylation. The neutralized organic layer of raw alkyl phenols is separated from the aqueous solution of salts and sent to vacuum distillation, in which water, olefin residues and unconverted phenol are distilled off.

In processes for the production of alkylphenols from gaseous olefins, it is expedient to use not a reactor with a stirrer, but an empty column in which the reaction mass is stirred by bubbling the olefin. The heat of reaction can be removed using internal or external coolers. To switch to a continuous process in order to intensify it and improve the composition of the reaction mass, as in other irreversible series-parallel reactions, it is more advantageous to use a cascade of such reactors.

In the process of alkylation of phenol in the presence of ion exchange resins, the catalyst is suspended in the liquid in the reaction column. Phenol and olefin are continuously fed to the bottom of the column. The reaction mass is filtered from the catalyst particles and fed to the distillation. The catalyst consumption is 0.4% by weight of the obtained alkylphenols.

Products received

The simplest phenol homologues: o-, m-, and p-cresols and isomeric xylenols:

One of the routes for their synthesis is the gas-phase methylation of phenol with methanol over a heterogeneous catalyst:

Of the monoalkylphenols, p-tert-butylphenol obtained from phenol and isobutene is of practical interest:

alkylation phenol carbohydrate aromatic

Monoalkylphenols with an alkyl group of 5–8 carbon atoms are strong bactericidal agents, and when it is extended to 8–12 carbon atoms, they turn out to be valuable intermediates for the synthesis of nonionic surfactants.

By the reaction of alkylation and acylation, alkyl and acyl groups can be introduced into aromatic compounds.

As already discussed earlier, phenols are alkylated into the ring under the action of a wide variety of alkylating agents:

- alkenes;

- alcohols;

- alkyl halides under conditions of acid catalysis.

Acylation of phenols is also carried out by various methods.

Friedel-Crafts Alkylation of Phenols

Phenol undergoes a Friedel-Crafts alkylation when treated with an alkylating agent, a Lewis acid such as $FeBr_3$ or $A1C1_3$ and a catalyst. In this case, salts of the $ArOAlCl_2$ type are formed. An example is the interaction of cresol with isobutylene to form a sterically hindered phenol - 2,6-di- tert-butyl-4-methylphenol (ionol):

Picture 1.

Similarly, by the reaction of phenol with isopropyl alcohol, 2,4,6-triisopropylphenol is obtained:

Figure 2.

In this Friedel-Crafts alkylation, the attacking electrophile is the alkyl cation formed by the reaction of the alkyl with a Lewis acid. In the absence of other nucleophiles, these electrophilic species react with the aromatic ring.

Friedel-Crafts alkylation has two important limitations that greatly reduce its value and make the reaction generally less advantageous than acylation. Alkylphenols are generally more reactive in electrophilic substitution reactions than phenol itself. Given this, Friedel-Crafts alkylation tends to further alkylate, resulting in the formation of dialkyl or more alkylated products, as shown in both cases discussed above.

The only practical way to control these substitution reactions is to maintain a large excess of phenol. This method is acceptable for benzene itself, because it is relatively cheap and volatile, but unacceptable for most of its substituted derivatives, which are more expensive or less available.

Another important limitation of Friedel-Crafts alkylation is related to the alternative reaction of many carbocations, in particular in the absence of reactive nucleophiles, namely the rearrangement into isomeric carbocations.

Carrying out monoalkylation according to Friedel-Crafts is characterized by extremely low regioselectivity and leads to mixtures ortho- And pair-isomeric products. Alkylation of phenols is a reversible reaction, and in the presence of strong Lewis acids, subject to thermodynamic control of the reaction, rearrangements occur:

Figure 3

Classic Friedel-Crafts Acylation of Phenols

Under classical conditions, the Friedel-Crafts acylation of phenols using complexes of the acyl halide with aluminum chloride leads to unsatisfactory product yields, since the hydroxyl group of the phenol also enters into the acylation. A more efficient method is acylation using a carboxylic acid complex with boron trifluoride as the acylating agent:

Figure 4

Condensation of phenols with phthalic anhydride

The condensation of phenols with phthalic anhydride in the presence of mineral acids or Lewis acids (A. Bayer, 1874) should also be considered as one of the varieties of the Friedel-Crafts acylation reaction. In this case, two phenol molecules condense with one phthalic anhydride molecule to form triphenylmethane derivatives called phthaleins.

Figure 5

At $pH$ above 9, aqueous solutions of phenolphthalein turn crimson as a result of the process of cleavage of the lactone ring with the formation of a dianion.

Figure 6

Aminomethylation

Figure 7

The Mannich reaction, or aminomethylation, is characteristic of compounds with an active methylene group. It occurs as a multicomponent reaction involving formaldehyde and a secondary amine (in the form of hydrochloride) and makes it possible to introduce the aminomethyl group $-CH_2NR_2$ into the compounds. Activated aromatic substrates, such as phenols, secondary or tertiary aromatic amines, heterocyclic compounds such as indole, pyrrole, and furan, also enter into the reaction. So you can get aromatic compounds with aminomethyl group $-CH_2NR_2$.

Among the amines, dimethylamine is often used, and another aldehyde can be introduced instead of formaldehyde.

The reaction mechanism consists in the formation of an imine salt with formaldehyde and a secondary amine through an intermediate aminal and its dehydration under the catalytic action of $H^+$. The iminium ion is an electrophile that attacks the aromatic ring. The iminium ion formed by formaldehyde and dimethylamine can be isolated as iodide (Eschenmoser's salt - $ICH_2NMe_2$).

Course work

Alkylation of phenols

Introduction 3

1. Characterization of alkylation processes 4

2. Chemistry and theoretical foundations of alkylation of phenols 10

3. Technology of the process of alkylation of phenols 14

4. Receipt products 15

References 18

Introduction

Alkylation is the process of introducing alkyl groups into the molecules of organic and some inorganic substances. These reactions are of great practical importance for the synthesis of aromatic compounds alkylated into the nucleus, isoparaffins, many mercaptans and sulfides, amines, substances with ether bonds, elemental and organometallic compounds, processed products of α-oxides and acetylene. Alkylation processes are often intermediate steps in the production of monomers, detergents, etc.

Many of the alkylation products are produced on a very large scale. Thus, about 4 million tons of ethylbenzene, 1.6 million tons of isopropylbenzene, 0.4 million tons of higher alkylbenzenes, over 4 million tons of glycols and other products of processing of alkylene oxides, about 30 million tons of isoparaffin alkylate, about 1 million tons of tert-butyl methyl ether, etc.

1. Characterization of alkylation processes

1. Classification of alkylation reactions

The most rational classification of alkylation processes is based on the type of newly formed bond.

Alkylation at a carbon atom (C-alkylation) consists in replacing the hydrogen atom located at the carbon atom with an alkyl group. Paraffins are capable of this substitution, but alkylation is most characteristic for aromatic compounds (the Friedel-Crafts reaction):

Alkylation at oxygen and sulfur atoms (O - and S-alkylation) is a reaction in which an alkyl group binds to an oxygen or sulfur atom:

ArOH + RCI ArOH + NaCl + H2O

NaSH + RCI → RSH + NaCI

In this case, processes such as the hydrolysis of chlorine derivatives or the hydration of olefins also fall under the too general definition of alkylation, and this shows that only such reactions of introducing an alkyl group that do not have other, more significant and defining classification features should be called alkylation.

Alkylation at the nitrogen atom (N-alkylation) consists in replacing hydrogen atoms in ammonia or amines with alkyl groups. This is the most important of the methods for the synthesis of amines:

ROH + NH3 → RNH2 + H2O

As in the case of hydrolysis and hydration reactions, N-alkylation is often classified as ammonolysis (or aminolysis) of organic compounds).

Alkylation at atoms of other elements (Si-, Pb-, AI-alkylation) is the most important way to obtain element - and organometallic compounds, when the alkyl group is directly bonded to the heteroatom:

2RCI + Si R2SiCI2

4C2H5CI + 4PbNa → Pb(C2H5)4 + 4NaCI + 3Pb

3C3H6 + AI + 1.5H2 → Al(C3H7)3

Another classification of alkylation reactions is based on differences in the structure of the alkyl group introduced into an organic or inorganic compound. It can be saturated aliphatic (ethyl and isopropyl) or cyclic. In the latter case, the reaction is sometimes called cycloalkylation:

With the introduction of a phenyl or aryl group in general, a direct bond is formed with the carbon atom of the aromatic nucleus (arylation):

C6H5CI + NH3 → C6H5NH2 + HCI

The alkyl group may include an aromatic nucleus or a double bond, and if the latter is sufficiently removed from the reaction center, the reaction differs little from the usual alkylation processes:

CH2=CH-CH2CI + RNH2 → RNHCH2-CH=CH2 + HCI

However, the introduction of a vinyl group (vinylation) occupies a special place and is carried out mainly with the help of acetylene:

ROH + CH≡CH ROCH=CH2

CH3-COOH + CH≡CH CH3-COO-CH=CH2

Finally, alkyl groups may contain various substituents, such as chlorine atoms, hydroxy, carboxy, sulfonic acid groups:

C6H5ONa + CICH2-COONa → C6H5O-CH2-COONa + NaCI

ROH + HOCH2-CH2SO2ONa → ROCH2–CH2SO2ONa + H2O

The most important of the reactions of introducing substituted alkyl groups is the process of -oxyalkylation (in a particular case, oxyethylation), covering a wide range of reactions of olefin oxides:

2. Alkylating agents and catalysts

All alkylating agents according to the type of bond that breaks in them during alkylation, it is advisable to divide into the following groups:

1. Unsaturated compounds (olefin and acetylene), which break the -electronic bond between carbon atoms;

2. Chlorine derivatives with a sufficiently mobile chlorine atom that can be replaced under the influence of various agents;

3. Alcohols, ethers and esters, in particular olefin oxides, in which the carbon-oxygen bond is broken during alkylation.

Olefins (ethylene, propylene, butenes and higher) are of paramount importance as alkylating agents. Due to their cheapness, they try to use them in all cases where possible. They have found their main application for the C-alkylation of paraffins and aromatic compounds. They are not applicable for N-alkylation and are not always effective in S- and O-alkylation and in the synthesis of organometallic compounds.

Alkylation with olefins in most cases proceeds according to the ionic mechanism through the intermediate formation of carbocations and is catalyzed by protic and aprotic acids. The reactivity of olefins in reactions of this type is determined by their tendency to form carbocations:

This means that the elongation and branching of the carbon atom chain in the olefin significantly increases its alkylation ability:

CH2=CH2< CH3-CH=CH2 < CH3-CH2-CH=CH2 < (CH3)2C=CH2

In some cases, alkylation with olefins proceeds under the influence of initiators of radical chain reactions, illumination, or high temperature. Here intermediate active particles are free radicals. The reactivity of different olefins in such reactions converges significantly.

Chlorine derivatives are alkylating agents of the widest range of action. They are suitable for C-, O-, S- and N-alkylation and for the synthesis of most elemento- and organometallic compounds. The use of chlorine derivatives is rational for those processes in which they cannot be replaced by olefins or when chlorine derivatives are cheaper and more accessible than olefins.

The alkylating action of chlorine derivatives manifests itself in three different types of interactions: in electrophilic reactions, in nucleophilic substitution, and in free radical processes. The mechanism of electrophilic substitution is characteristic of alkylation at the carbon atom, but, unlike olefins, reactions are catalyzed only by aprotic acids (aluminum chloride, iron chloride). In the limiting case, the process proceeds with the intermediate formation of a carbocation:

in connection with which the reactivity of alkyl chlorides depends on the polarization of the C-CI bond or on the stability of carbocations and increases with elongation and branching of the alkyl group:

In another type of reaction, characteristic of alkylation at oxygen, sulfur and nitrogen atoms, the process consists in the nucleophilic substitution of the chlorine atom. The mechanism is similar to the hydrolysis of chlorine derivatives, and the reaction proceeds in the absence of catalysts:

The reactivity of chlorine derivatives changes in these processes in the same way as during hydrolysis, namely:

ArCH2CI > CH2=CH-CH2CI > AIkCI > ArCI

prim-AIkCI > sec-AIkCI > tert-AIkCI

A number of alkylation processes with chlorine derivatives proceed according to the free radical mechanism. This is especially typical for the synthesis of elemental and organometallic compounds, when free radicals are formed due to interaction with metals:

4PbNa + 4C2H5CI → 4Pb + 4NaCI + 4C2H → 4NaCI + Pb(C2H5)4 + 3Pb

Alcohols and ethers are capable of C-, O-, N- and S-alkylation reactions. Olefin oxides, which are internal ethers of glycols, can also be classified as ethers, and of all ethers, only olefin oxides are practically used as alkylating agents. Alcohols are used for O - and N-alkylation in cases where they are cheaper and more accessible than chlorine derivatives. To break their alkyl-oxygen bond, acid-type catalysts are required:

R-OH + H+ ↔ R-OH2 ↔ R+ + H2O

3. Energy characteristics of the main alkylation reactions

Depending on the alkylating agent and the type of bond breaking in the alkylated substance, alkylation processes have very different energy characteristics. The values of thermal effects for the gaseous state of all substances in some important processes of alkylation at C-, O- and N-bonds are given in Table 1. Since they significantly depend on the structure of alkylating substances, the table lists the most common ranges of changes in thermal effects.

Table 1

Thermal effect of the most important alkylation reactions

Alkylating agent

A broken bond

![]()

It can be seen from a comparison of the given data that when using the same alkylating agent, the heat of reaction during alkylation at different atoms decreases in the following order Car > Salif > N > O, and for different alkylating agents it changes as follows:

The especially large thermal effect of alkylation with the participation of ethylene oxide and acetylene is due to the significant tension of the three-membered oxide cycle and the high endothermicity of compounds with a triple bond.

2. Chemistry and theoretical foundations of alkylation of phenols

Phenols form inactive ArOAICI2 salts with AICI3; therefore, protic acids or acid-type metal oxide catalysts are used as catalysts for the alkylation of phenols. This allows only alcohols and olefins to be used as alkylating agents. Along with substitution products in the core, some phenol ethers are obtained, which are easily rearranged into alkylphenols:

It has been established that alkylphenols are predominantly formed by direct alkylation to the core. The mechanism of this reaction is similar to the mechanism for aromatic hydrocarbons, and the hydroxo group of phenols strongly activates, especially the 4- and 2-positions, with the almost complete absence of meta-isomers in the products.

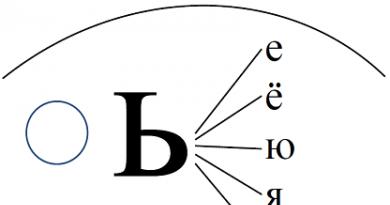

Alkylation proceeds sequentially with the formation of mono-, di, and trialkylphenols, but simultaneously acid-catalyzed rearrangement occurs with the migration of ortho-alkyl groups to form para-isomers, which in this case are the most thermodynamically stable. Thus, the transformation scheme is as follows:

Of the monoalkylphenols catalyzed by protic acids, the para isomer always predominates, but with an increase in the activity of the catalyst, the temperature, and the duration of the reaction, the proportion of this isomer among the monosubstituted ones can increase from 60–80 to 95% or more due to the isomerization of the ortho isomer.

Of the disubstituted, 2,4-dialkylphenol always predominates significantly, the proportion of which increases even more under the above conditions.

With the sequential introduction of alkyl groups, in contrast to the alkylation of aromatic hydrocarbons, the first stage proceeds faster than the second, and the last faster than the third. The composition of the products of sequential substitution is affected by the reversible transalkylation reaction:

R2C6H4OH + C6H5OH ↔ 2RC6H4OH